- Your cart is empty

- Continue Shopping

What are the steps to make complete dentures?

If your dentist says that you need dentures, then don’t worry. It is common to numerous people. In fact, dentures are a must if your dentist advises you to have them. There are expert technicians who can prepare perfect dentures as per your shape and size. These will be customized as per your mouth and you will feel comfortable without any issue.

Now you may ask what are the steps to make complete dentures. Let’s enter into the details of it.

Is it First Time for You?

If this is for the first time with you, then you might feel awkward. You might feel some difference in taste, sensation and while speaking also. But, it will help you in various aspects including your health and hygiene. Now the question arises, whether you are looking for a permanent solution or a temporary one? You need to convey your thought to your dentist as well as to the technician who will develop your dentures.

Denture Material

Dentures can be made of acrylic or metal-based allow or even resin-based also. Thermoplastic polymer and other materials are also used nowadays to prepare dentures. The proper material needed for you can only be judged once the dentist physically examines your mouth and teeth area. Based on that, he can give the best direction. Also, the material varies depending on whether you need a partial or complete denture or even a permanent or temporary solution. It depends on a lot of things.

Steps to make complete denture

- Step 1: At first, you need to take a preliminary impression of the patient’s mouth by using stock trays. It might be required to enhance the periphery of the tray if needed. Then you have to pour the impression in the dental stone using a vibrator. The use of vibrator for eliminating any void or bubbles.

- Step 2: Next, the technician needs to fabricate a customized impression tray as well as wax bite rims. The bite rims are needed to give perfect lip support

- Step 3: The next step is articulating the models. Articular is used for the exact measurement of the rim.

- Step 4: The teeth will be set up now in perfect form and shape.

- Step 5: After the teeth are set up correctly, then additional wax is fixed around the teeth to make the perfect shape. Also, it helps in developing perfect gingival contour. It makes it look like the original and the excess wax can be removed slowly to give the best fit.

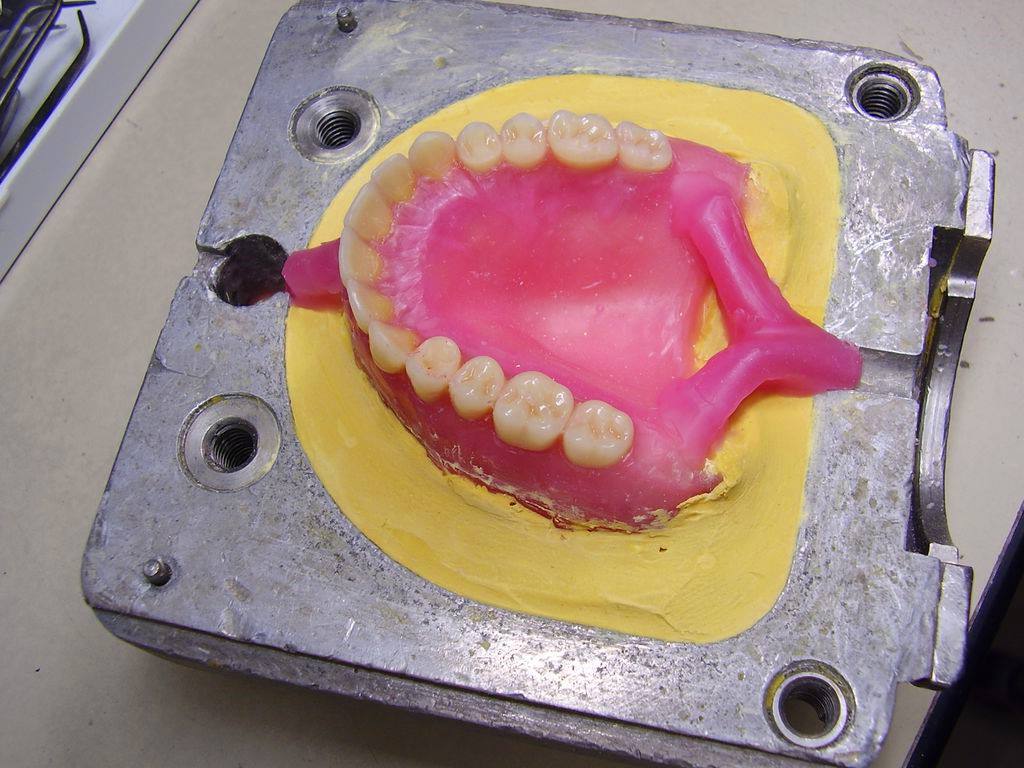

- Step 6: The next step is flasking where the denture is flasked with the bottom part. When the plaster is dried then the upper part is extracted and subsequently filled with additional plaster if required. Then after opening the flask, redundant wax is flushed out accordingly.

- Step 7: Acrylic mixing is also another important step where monomer and polymer are weighed. These are mixed in the right proportion to form the acrylic.

- Step 8: Once the mold is prepared, the acrylic is poured into the flask. Two halves are placed back to back and are kept under pressure to have the best hardness. It is required so that your denture can eat or chew any item like the normal one.

- Step 9: A finishing touch is given in this step with special burs for removing any excess acrylic around the palatal area and other edges. Articulation is also checked and adjusted if any requirement arises.

- Step 10: The last step is polishing the denture to make a smooth one. In this process, it will look like your original one.

Items and Tools used in the process

In the entire process, several items are used in order to make a perfect denture. For example, there is a dental laboratory model trimmer. It is necessary for trimming the refractory or gypsum cast. There are dry, wet, or both combination available as per requirement. If you are using a dry trimmer, then a dust retraction device should be available with you. Even one can choose single wheel or dual wheel trimmers for rough cutting and finishing works.

Also, sandblasting machine dental equipment is an important part if you want to know in detail about what are the steps to make complete dentures. These are used to increase the bonding strength by increasing the effective surface area. It divests the casting investment and polishes the restoration surface. These are operated either by an air compressor or by a vacuum way.

Denture bur is used for general cutting hard tissues – either of the tooth or of bone. Generally, these are made of stainless steel or tungsten carbide. There are different types of dental burs available for various activities. But, all the burs are having a head and a shank.

Dowel dentistry is also a related term where a dowel is noticed when there is a huge loss of coronal tooth structure. Also, it is found in the case of a tooth serving as an abutment for a fixed or removable denture partially. Dowel crown is associated with this concept.

You need to have the best dental mirror also for preparing the perfect denture. There are so many available in the market. But the best should have all the qualities and requirements that a mirror should have. For example, it must be equipped with a bright LED light to inspect deep areas. The mirror glass should be the best and it should reach every corner of your mouth. Remember, this inspection mirror can be effective if you regularly use that to check every area inside your mouth. Then only, you can get benefit out of that.

Dental lab boxes are also an important aspect in terms of your dentures. You must pack the item in a perfect shape and sized box. A lot of damage is reported if the packaging is not good. The boxes should be made enough strong to handle the transportation from one city to another within another big container if needed.

So, here are the steps to make a complete denture and along with its supportive tools that are must in order to make any denture. The steps may vary from one person to another person, from one material to another material. But the overall process remains the same and one can follow it for any purpose.