- Your cart is empty

- Continue Shopping

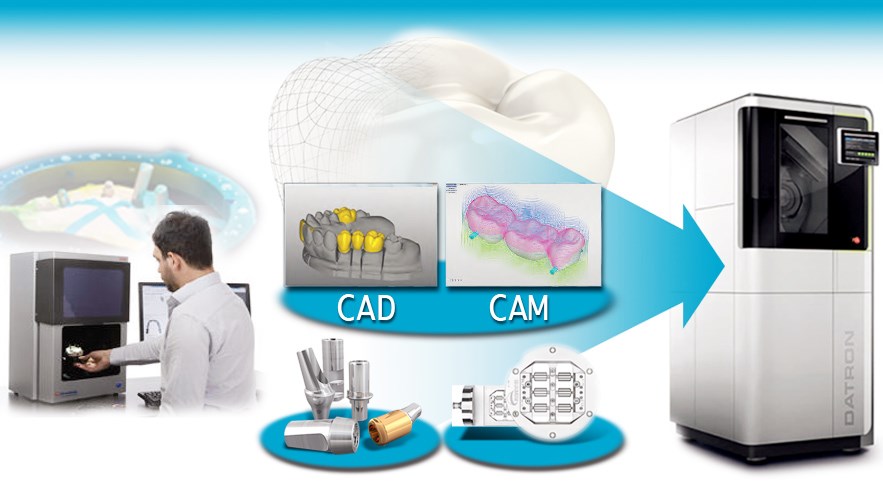

Brief introduction of ten representative dental CAD/CAM systems

Computer-aided design and production technology was the first high-tech technology applied in industrial automation. After long-term research by dentists and scientific and technical personnel, CAD/CAM systems have been rapidly developed, commercialized, and applied in clinics. In the 1970s, I mainly stayed on theoretical research. In 1973, French dentist Duret published the first paper on the application of CAD/CAM in oral cavity. Since then, the scope of research has gradually expanded, and the number of researchers has gradually increased. In 1983, the first prototype using CAD/CAM technology to make restorations came out in France. In 1985, a prototype of Duret’s restoration using CAD/CAM technology came out in France. In 1985, Duret used the CAD/CAM prosthetic production system to demonstrate the production of a posterior full crown restoration.

So far, there are more than 10 kinds of dental CAD/CAM systems in the world, and several representative systems are introduced below.

(1) Duret system (French system): The system was developed by a research team led by Duret. The main principle is to use electron optics to obtain an optical impression of the tooth preparation-digitalization-input computer-preparation of three-dimensional three-dimensional images- Design restorations-make restorations. The system is most developed and perfected by the French company Sopha Bioconcept, also known as the Sopha Duret system. The maxillofacial design is based on the situation of the opposite jaw, and the maxillofacial cusp relationship is established in the median jaw position. Can process ceramic materials and titanium alloys.

(2) Cerec system (Swiss system): Cerec (chariside economical restoration of esthetic ceramics) is the abbreviation for “chairside restoration of aesthetic ceramics”. This system was jointly designed and developed by dentist Mormann and engineer Brandetini. It was first published in 1986 Exhibited in Zurich, Switzerland, the system consists of a three-dimensional intraoral camera, monitor, keyboard, trackball, cutting lathe, image processing, and processing software. It is mainly used for processing ceramics.

In 1994, CEREC2 had a faster microprocessor and a higher and higher resolution camera. The grinding system added grinding burs. Later, due to the development of software, CEREC2 can produce all-ceramic crowns and complete maxillofacial shapes. All-ceramic crown.

CEREC3, which was born in 2000, is based on the windows platform. The grinding system and the image acquisition system of the movable system work independently, and can produce inlays, onlays, full crowns, partial crowns and veneers. But at this time, the software can only show the planar effect of the restoration, and cannot observe the restoration as a whole. Sirona launched CEREC inLab in 2002, which was designed for dental technology studios, using indirect methods to make restorations without using intraoral camera equipment. The CNC machining unit completes the three-dimensional measurement and acquisition of the plaster model and the conical bur. The restorations obtained by grinding and cutting often need to be further processed in the laboratory according to the situation. For example, restorations made with prefabricated ceramic blocks such as Vita Mark II are uniform in color and need to be personalized, and can be dyed and glazed in different colors; while the Vita-Ceram series of prefabricated ceramic bodies are used. All-ceramic crowns, bridge-bottom crowns or stents need to go through processes such as glass penetration, surface decoration, and glazing to complete the restoration.

CEREC 3D, launched in 2003, solved many problems of previous models. It introduced a multi-dimensional perspective and highly intuitive interface when designing restorations. Users can observe and evaluate the designed restorations from a three-dimensional perspective, and use virtual tools to view the computer screen. Edit and modify the objects displayed on the screen. The CEREC 3D system has further strengthened the production functions of all-ceramic inlays, veneers, and full crowns. With the addition of new 3D design software such as FrameWork and the application of new materials such as zirconia ceramics, all-ceramic fixation has been realized. The making of the bridge.

Cerec system is currently one of the most complete dental CAD/CAM systems. It is estimated that there are nearly 2,000 Cerec systems applied and clinically in the world. Clinical data show that all-ceramic restorations made by Cerec system have a high success rate and repair effect. Good.

(3) Cerec system: The Zirkon zahn system is composed of a contact digital instrument and a micro milling machine. Its working principle is similar to that of a key. It is not a CAD/CAM system in the complete sense. The digitizer “reads” and takes it in the mouth. Or the surface morphology of the resin inlay and crown made on the model, the morphological information is directly transferred to the milling machine for copy processing, so it is also called “copy grinding and cutting system”.

The Celay system was developed by the University of Zurich in Switzerland and produced by Mikroma. In the 1990s, the University of Zurich cooperated with the Vita company to combine the Celay system with In-Ceram technology and launched the Celay/In-Ceram all-ceramic restoration system. The Celay system was used to process pre-sintered porous alumina blocks, and then infiltration was used. Ceramic technology. This method not only does not require long-term sintering of the alumina bottom layer (usually about 10 hours), but also shortens the glass penetration time from about 4 hours to about 40-50 minutes. Compared with conventional infiltrating ceramic technology, this method can produce infiltrated ceramic restorations in one day. At present, the Celay/In-Ceram all-ceramic restoration system includes not only Celay/In-Ceram Alumina, Celay/In-Ceram spinell, but also Celay/In-Ceram Zirconia, which can be used for the production of single crowns and fixed bridges respectively.

(4) Kavo Everest CAD/CAM system: Kavo Everest system is a set of dental laboratory CAD/CAM system launched by KaVo in Germany in 2003. It consists of scanner, computer-aided design system, CNC It is composed of lathe, sintering system, special materials and supporting professional technicians. This system is a more mature CAD/CAM system integrating data collection, design, and production. It can be used to make porcelain inlays, onlays, veneers, all-ceramic crowns and all-ceramic core crowns. All-ceramic fixed bridge bracket with a length of 45 mm.

(5) Procera AllCeram system: The Procera AllCeram system was designed by Andersson and Oden, jointly developed by Sweden Nobel Biocare AB and AB Sandivk Hard Materials, and was exhibited for the first time in Switzerland in 1987. The system consists of two parts: CAD/CAM. The CAD part includes Procera precision processing machine and industrial molding technology, which can be accurately processed according to the data.

After general tooth preparation, take the model, make the active model, use the Procera scanner to scan the model, obtain the three-dimensional data, generate the three-dimensional digital model in the computer, and then design the all-ceramic bottom crown according to the actual required thickness. Transmit the designed digital model and bottom crown data to the Procera workstation via the Internet. The Procera CAM of the workstation accurately converts the amplified digital model to the mechanical model based on the data received, and then uses industrial dry pressing technology to convert Procera CAM alumina porcelain with a purity of over 99.9% under high pressure. The fine powder is pressed on the surface of the machine-made model to form an alumina bottom crown body. After the bottom crown body is removed from the model, it is densely sintered at a high temperature of 1550 °C. After sintering, the alumina bottom crown is translucent and ivory, with a strength of more than 600MPa, which has good suitability. After the workstation is completed, it is mailed back to the mechanic processing center, and the veneer porcelain is piled up to complete the restoration.

(6) Cercon system: In 2002, Cercon smart ceramics zirconia ceramics were launched, with a flexural strength greater than 1300MPa. Zirconia all-ceramic material is currently the ceramic material with the highest bending strength among oral ceramics, and it has gradually been widely used in the restoration of all-ceramic bridges. This system is a CAM system dedicated to cutting zirconia ceramics launched by Degussa. The pre-sintered porcelain block has different length specifications of 12mm, 30mm, 38mm, 47mm, and the longest can be 6 units of pontics. Its average linear shrinkage rate is 29%. The pre-sintered porcelain block is very crisp and is called chalk. Like (chalk-hard), it needs to be trimmed manually after cutting. The sintering temperature is 1350 °C for about 6 hours. The veneer porcelain is a specially developed material (Cercon ceram), which wants to match the thermal expansion coefficient of the zirconia stent.

(7) LAVA system LAVA all-ceramic restoration system is a CAD/CAM system designed and developed by 3M ESPE company. It was launched in 2003. It is mainly used for the production of zirconia all-ceramic crowns and stents. Its basic structure and principle, The function, is similar to Kavo Everest Cercon. The system consists of high-precision scanner, CAD design software, grinding and cutting system and sintering furnace.

CAD/CAM Dentistry material reference:

- Pre shaded dental zirconia block

https://www.dentallaboratorio.com/product/preshaded-zirconia-zirkon-zahn-blocks-copy/

- Dental milling burs

https://www.dentallabshop.com/product/sirona-mc-xl-dental-carbide-burs/

- White color super translucent dental zirconia block

https://www.dentallaboratorio.com/product/st-zirkonzahn-zirconia-block/

- Pmma dental material

https://www.dentallabshop.com/2021/03/02/feature-of-pmma-dental-material-used-in-dentistry-cad-cam/